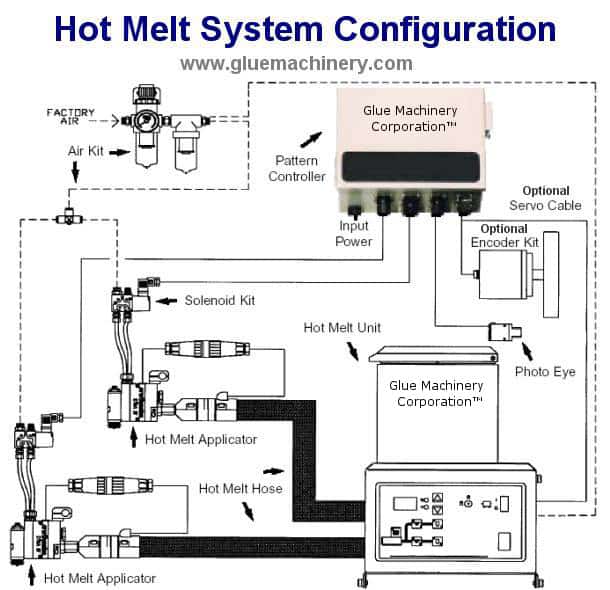

Compatible With:

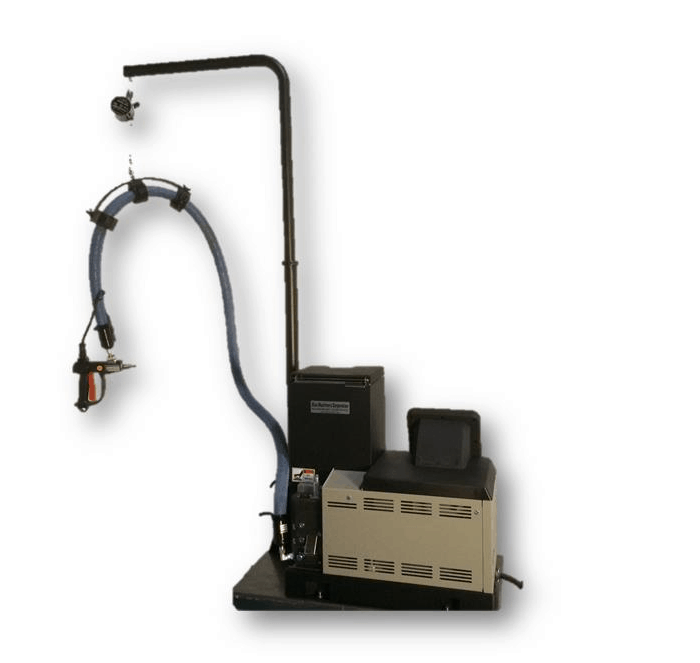

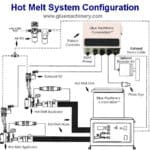

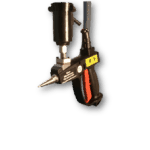

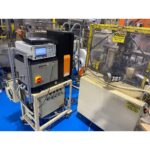

Most Hot Melt Adhesives, Hot Melt Hoses, Manual High Flow Guns, Automatic Hot Melt Guns, Pattern Controllers & Detectors.Product Manuals / Related PDFs:

Guide: How to Eliminate Hot Melt "Stringing" S Series Tank Product Manuals are available from Glue Machinery Corporation - 1-888-202-2468SR Series - High Performance Hot Melt Tanks

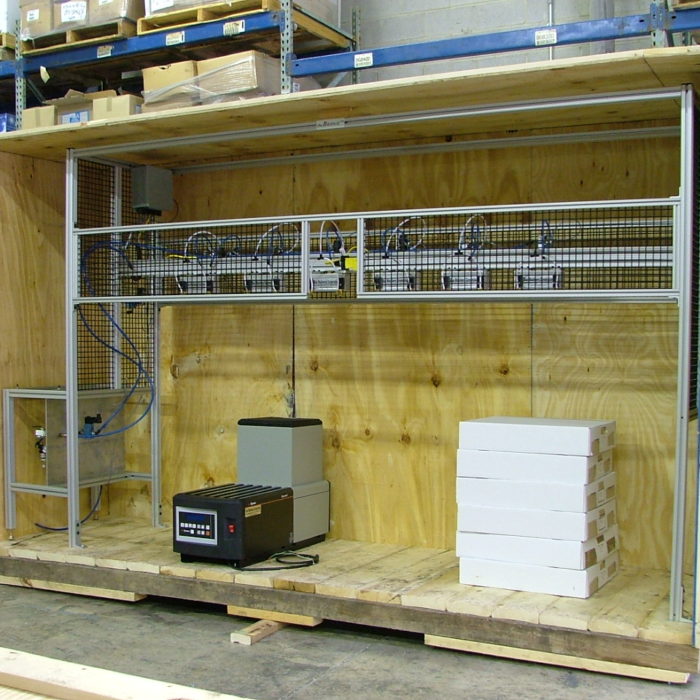

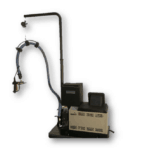

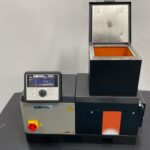

10/20/48/100 lb hot melt tanks with Melt on Demand reservoir.

$QUOTE THIS MACHINERY

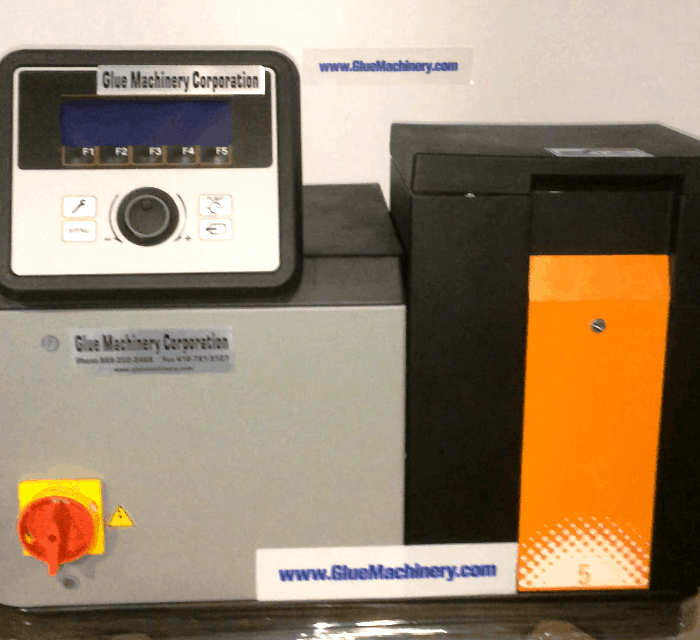

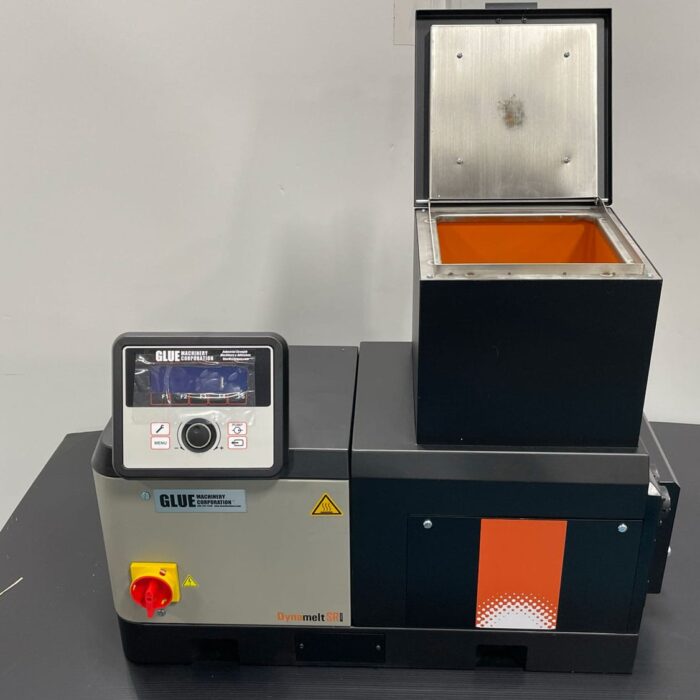

SR Series Hot Melt Tanks

Call 1-410-761-2727Or Fill Out The Form Below

Product Details:

SR Series Hot Melt Adhesive System:- 10, 20, 50, 100 lb capacity.

- 2, 4 and 6 hoses gun capable.

- 100-450ºF operating temperature range.

- ± 1ºF temperature accuracy.

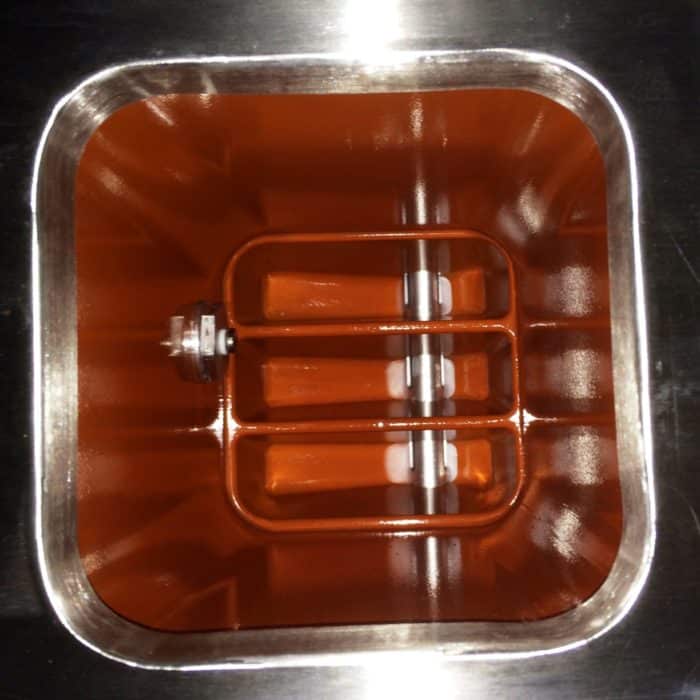

- Patented "Melt on Demand" tank configuration.

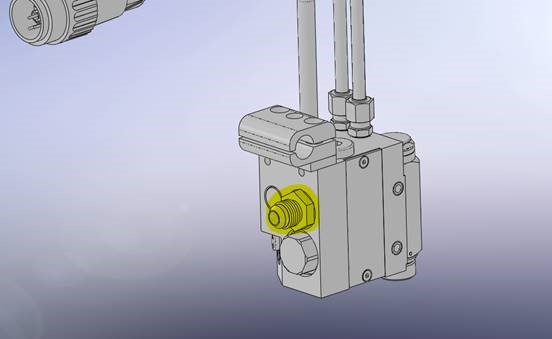

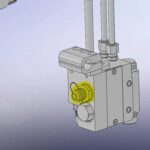

- Piston pump or choice of variable speed gear pump.

- 120 or 240 VAC.

| System | SR | SR10 | SR22 | SR45 |

| Hopper Capacity | 10 lbs (5kg) | 22 lbs (10kg) | 48 lbs (22kg) | 100 lbs (45kg) |

| Operating Temperature | 50 to 425°F 10 to 218°C | 50 to 425°F 10 to 218°C | 50 to 425°F 10 to 218°C | 50 to 425°F 10 to 218°C |

| Melt Rate/Hour* | 23 lb/hr 10 kg/hr | 23 lb/hr 10 kg/hr | 50 lb/hr 22 kg/hr | 51 lb/hr 23 kg/hr |

| Pump Rate per minute* (Piston / 4.5cc Gear) | 2 lb (.91kg) / .83 lb (.38kg) | 2 lb (.91kg) / .83 lb (.38kg) | 2 lb (.91kg) / .83 lb (.38kg) | 2 lb (.91kg) / .83 lb (.38kg) |

| Piston Pump Compression Ratios | 12:1 | 12:1 | 12:1 | 12:1 |

| Gear Pumps Standard | from 0,16 to 20 ccm/rev | from 0,16 to 20 ccm/rev | from 0,16 to 20 ccm/rev | from 0,16 to 20 ccm/rev |

| Hose Output Zones | 2, 4, or 6 | 2, 4, or 6 | 2, 4, or 6 | 2, 4, or 6 |

| Max Working Hydraulic Pressure | 1,000 psi (68 bar) Piston Pump | 1,000 psi (68 bar) Piston Pump | 1,000 psi (68 bar) Piston Pump | 1,000 psi (68 bar) Piston Pump |

| Temperature Control Stability | ± 1°F (1°C) | ± 1°F (1°C) | ± 1°F (1°C) | ± 1°F (1°C) |

| Electrical Service Standard 1 | 200- 240 VAC 1Phase 50/60 Hz 200-240 VAC 3Phase 50/60 Hz | 200- 240 VAC 1Phase 50/60 Hz 200-240 VAC 3Phase 50/60 Hz | 200- 240 VAC 1Phase 50/60 Hz 200-240 VAC 3Phase 50/60 Hz | 200- 240 VAC 1Phase 50/60 Hz 200-240 VAC 3Phase 50/60 Hz |

| Electrical Service Standard 2 | 240/400 VAC 3Phase Y 50/60 Hz | 240/400 VAC 3Phase Y 50/60 Hz | 240/400 VAC 3Phase Y 50/60 Hz | 240/400 VAC 3Phase Y 50/60 Hz |

| Working Viscosity | 500 – 50,000 cps | 500 – 50,000 cps | 500 – 50,000 cps | 500 – 50,000 cps |

| Dimensions | SR5 New | SR10 New | SR22 | SR45 |

| Height (H) | 20.96 in (53.23 cm) | 26 in (66.04cm) | 36.1 in (91.8 cm)† | 52.1 in (132.4 cm)† |

| Depth (D) | 16.8 in (42.67 cm) | 16.8 in (42.67 cm) | 18 in (45.6 cm)† | 18in (45.6 cm)† |

| Width (W) | 25.79 in (65.5 cm) | 25.79 in (65.5 cm) | 33.5 in (85.1 cm) | 33.5 in (85.1 cm) |

| Weight (empty) | 129 lbs (59kg) | 138 lbs (63kg) | 177 lbs (80kg) | 198 lbs (90 kg) |

Optional Accessories

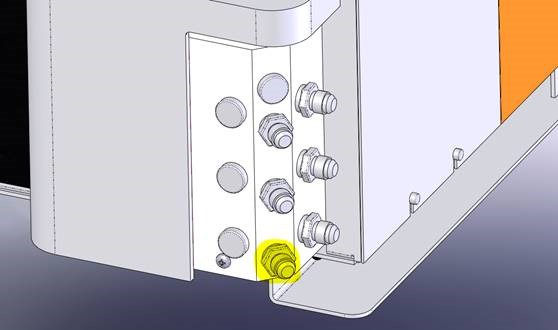

- Analog or digital pressure gauge

- Adhesive low level sensor

- Tethered pendant controller display

- 480 VAC transformer

- Drop-in heating grid (SR10, SR22, and SR45 only)

- Ethernet module