What does the typical automatic hot melt system used in packaging consist of?

What does the typical automatic hot melt system used in packaging consist of?

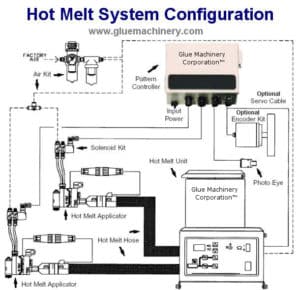

Easy; one hot melt tank, one or more flexible heated hoses, automatic hot melt guns, nozzles, solenoids, and pattern controls.

To determining the correct configuration of the hot melt packaging systems you must first answer the following questions:

-

- What patterns are required to seal your package?

- How much hot melt will you use per hour?

- How far will the tank be positioned from the applicators?

- How fast will the packaging line run?

- What hot melt will you use?

The quantity of hot melt used per hour will determine the minimum size and melt rate of the hot melt tank and the type of pump provided with the tank. The distance the guns are from the tank will determine hose lengths. The pattern required will determine the type of automatic hot melt guns, nozzles, solenoid, and pattern controls used to actuate the gun as well as the type of pump used on the tank.

To determine the hourly consumption as well as the gun and nozzle configuration – provide the following:

- Number of dots or beads on the carton or case

- Bead profile and width before compression

- Length of dots and beads

- Number of cartons or cases per minute

Call us at 1 (888) 202-2468 or email us with this information and we will provide basic system options available.