EVA glue is an adhesive made from ethylene-vinyl acetate copolymer. It stands out as a top choice for those seeking a robust, durable, and waterproof bonding material suitable for various materials.

This adhesive is incredibly versatile and finds its use both in craft and DIY as well as industrial sectors. Its unique property allows it to bond a diverse range of materials, including wood, metal, glass, ceramics, and even certain plastics. This adaptability makes it a go-to adhesive for numerous projects.

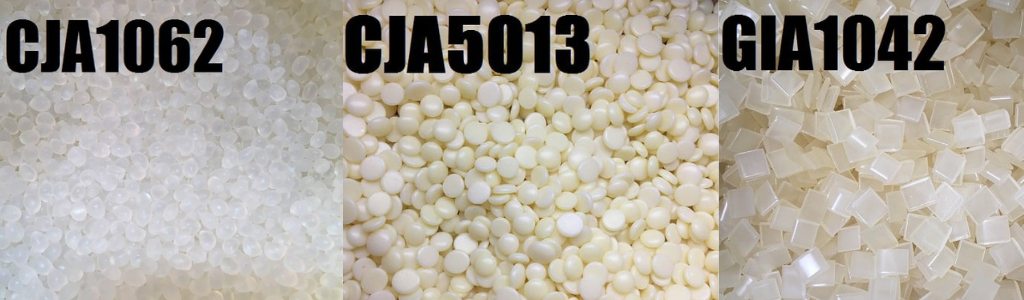

EVA hot melt adhesive is a 100% solid, transparent, flexible Ethylene Vinyl Acetate Copolymer. It is normally categorized by percent VA content and melt flow rate (MFR) or melt index (MI). Most commonly used EVAs contain between 19% and 28% VA. The MI values are mostly ranging from 3 to 2500.

In an EVA-based HMA formulation, a greater VA content can result in higher transparency, more polar, extended flexibility, and better wettability to substrates. The MI value is a simple indicator of molecular weight. A lower MI value reflects a higher molecular weight, cohesion, and internal strength.

Key Features of EVA Glue:

Heat Resistance: EVA glue can withstand temperatures up to 450-800 degrees

Celsius before breaking down, that’s almost 1,500 degrees Fahrenheit!.

Durability: It offers a strong, water-resistant bond, ensuring longevity in its applications.

Safety: One of the significant advantages of EVA glue is its non-toxic and non-flammable nature, making it safe around children and pets.

Versatility: EVA glue is available in various thicknesses and colors, catering to a wide range of applications.

EVA Adhesive Formulation

Most EVA-based HMAs do not have significant surface tack and are not pressure sensitive at room temperature. They need to be bonded at elevated temperatures by hot tack. They normally impart relatively short open time (typically less than 10 seconds) and fast set time. Open time and set time are primarily determined by the wax used – if it is included in the formulation, VA content, and the compatibility of EVAs and tackifiers. Typical waxes used in hot melt adhesive formulations are synthetic, micro-crystalline and polyethylene wax. Waxes can significantly shorten the open time and speed up set time. EVAs with more VA content will offer longer open time and slower set time.

Technical properties of EVA Glue

EVA adhesives are known for their versatility, bonding to a wide variety of substrates and functioning across a broad temperature range. Among the various hot melt adhesives available in the market, EVA stands out as one of the most cost-effective options. When it comes to application, EVA hot melt adhesives typically require a melting temperature of around 350 degrees F.

Another notable property of EVA is its viscosity range, which spans between 900 to 3,000 cPs. In terms of setting, EVA adhesives are generally quick to set. However, those with a higher ratio of vinyl-acetate might take a bit longer. Furthermore, based on the specific formulation, EVA adhesives can operate in extreme temperatures, ranging from as low as -40 degrees F to as high as 160 degrees F.

Applications of EVA Adhesives

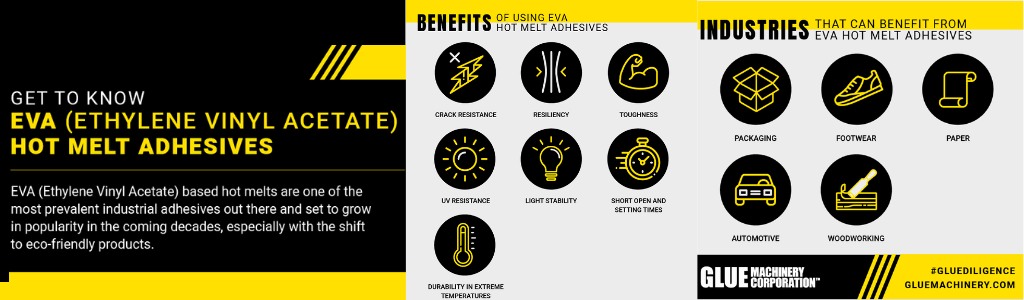

EVA hot melt adhesives are a testament to versatility in the world of adhesives. Their adaptability has made them a preferred choice in a myriad of industries, each with its unique requirements.

Paper Industry

In the paper industry, EVA adhesives play a crucial role in ensuring that products are durable and well-bonded. They are especially useful in binding books, attaching labels, and even in the production of laminated paper products.

Woodworking

EVA’s strong bonding capability is invaluable in woodworking. Whether it’s for furniture assembly, bonding veneers, or even in the production of cabinetry, EVA ensures that wooden components remain firmly attached.

Assembly

In the assembly line, speed and efficiency are of the essence. EVA adhesives, with their fast set speed, are ideal for rapid assembly processes, ensuring that products are manufactured at a swift pace without compromising on the quality of bonding.

Automotive

The automotive industry demands adhesives that can withstand varying temperatures and conditions. EVA adhesives are used in the interior assembly of vehicles, bonding fabrics, foams, and other components. Their resistance to temperature fluctuations makes them a reliable choice for this sector.

Packaging

The packaging industry is perhaps one of the most significant beneficiaries of EVA adhesives. Their ability to adhere to a diverse range of materials, from waxes to aqueous coatings, makes them indispensable. Applications include carton sealing, package labeling, and paper conversion, ensuring that products are securely packaged and labeled.

Footwear

EVA adhesives have also found their footing in the footwear industry. They are extensively used in bonding various parts of a shoe, especially the sole. Given the wear and tear shoes undergo, a robust adhesive like EVA ensures longevity. Whether it’s sports shoes, formal footwear, or casual sandals, EVA adhesives play a pivotal role in their construction.

In conclusion, EVA hot melt adhesives are a cornerstone in many industries, offering tailor-made solutions to diverse bonding needs. Their adaptability, strength, and cost-effectiveness make them a preferred choice for industries ranging from packaging to footwear. If there’s a need for reliable and robust adhesion, EVA is often the answer.

EVA Vs PVA Glue

EVA and PVA glues are both versatile adhesives, each with its distinct characteristics and applications. EVA glue, made from a blend of ethylene and vinyl acetate, is renowned for its robust bonding, flexibility, and water-resistance, making it a preferred choice for packaging, assembly, and certain crafting needs.

On the other hand, PVA glue, derived from polyvinyl acetate, is water-soluble, non-toxic, and dries clear. It’s especially favored in woodworking and arts and crafts, particularly when working with paper. While EVA offers a stronger bond suitable for diverse materials and conditions, PVA stands out for its safety and efficacy in bonding wood and paper, making it a staple in carpentry and school projects.

EVA Terminology

These are some terms you may run into while looking into EVA adhesive solutions.

Hot tack is a term relating to the ability of HMAs to hold substrates together prior to solidification or set.

Open time is the time after the EVA adhesive is applied during which a serviceable bond can be made. Many factors affect open time, including temperature, substrate, adhesive, and amount of adhesive applied.

Set time is the time it takes to form an acceptable bond when two or more substrates are combined with an adhesive.

When EVAs are blended with various tackifiers, they may exhibit a different open time, set time, cloud point and specific adhesion performance – depending upon the type of tackifiers used or their compatibilities.

Cloud point is the temperature at which an HMA becomes cloudy upon cooling from a molten to a solid stage. Cloud point is a good indication of the compatibility of the formula components.

Generally, when EVAs and tackifiers are more compatible, the blended HMAs are more transparent. Moreover, they can exhibit a lower cloud point, longer open time, slower set time and better adhesion to varied substrates.

In practice, a balance of open time and set time are key parameters to ensure satisfactory bonding and therefore obtain optimum adhesion performances. Besides those effects resulting from VA content, the polarity of tackifiers is another important factor which will significantly affect the degree of physical adsorption between the interface of hot melt adhesives and substrates. Hot Melt Adhesives with higher physical adsorption will result in a better wetting and adhesion.

In summary, there is no ideal EVA Hot Melt Adhesive formulation for diversely bonding applications. The optimal formulation must be developed specifically to the substrates to be bonded (polarity and surface roughness), application techniques (applicators, speed, and bonding temperature), and the end users’ servicing environment (temperature and humidity).

Frequently Asked Questions

What is the strength of EVA glue?

EVA glue is known for its robust bonding capability. Its strength can vary based on its formulation, but it generally offers a durable and water-resistant bond suitable for a wide range of materials, from paper to certain plastics.

Is EVA glue safe?

Yes, EVA glue is generally considered safe and non-toxic. However, like all adhesives, it’s essential to use it in well-ventilated areas and keep it out of reach of children. Always follow the manufacturer’s safety guidelines when using EVA glue.

What is the best adhesive for EVA foam?

The best adhesive for EVA foam is typically EVA glue itself, especially in its hot melt form. Given that they’re made from the same base materials, EVA glue naturally adheres well to EVA foam, providing a strong and lasting bond.

Can you use super glue on EVA foam?

While super glue (cyanoacrylate) can bond EVA foam, it might not be the best choice for all applications. Super glue can sometimes be too rigid or brittle for the flexible nature of EVA foam. For projects requiring flexibility, EVA glue or a flexible adhesive is recommended.

Is e6000 EVA glue?

No, e6000 is not EVA glue. e6000 is a popular industrial strength adhesive known for its flexibility and versatility. It’s a unique adhesive formulated to meet high-performance industrial requirements, and while it can bond EVA foam, it’s not made from ethylene-vinyl acetate like EVA glue.