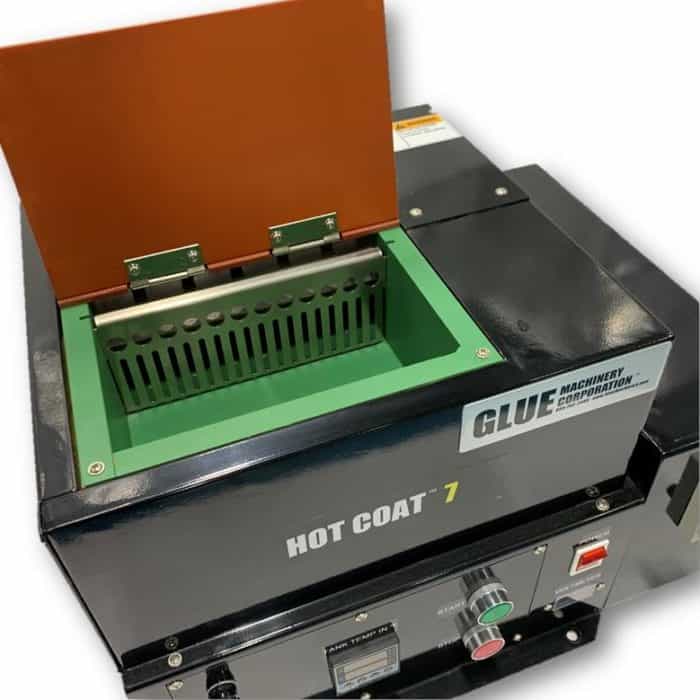

Hot Coat™ 7 Industrial Hot Melt Roll Coater

$Product Videos (Click to View)

Hot Coat 71 Foam to Plastic2 Foam to Foam3 Foam to foam4 plastic to wood5 Foam to Plastic Face Shield6 Cornerboard Reinforcements7 Removing Hot Melt8 Foam to FRP9 Foam to FRP10QUOTE THIS MACHINERY

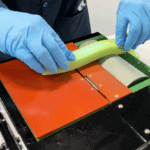

Hot Coat™ 7

Call 1-410-761-2727Or Fill Out The Form Below

Product Details:

- Variable Speed Motor Drive

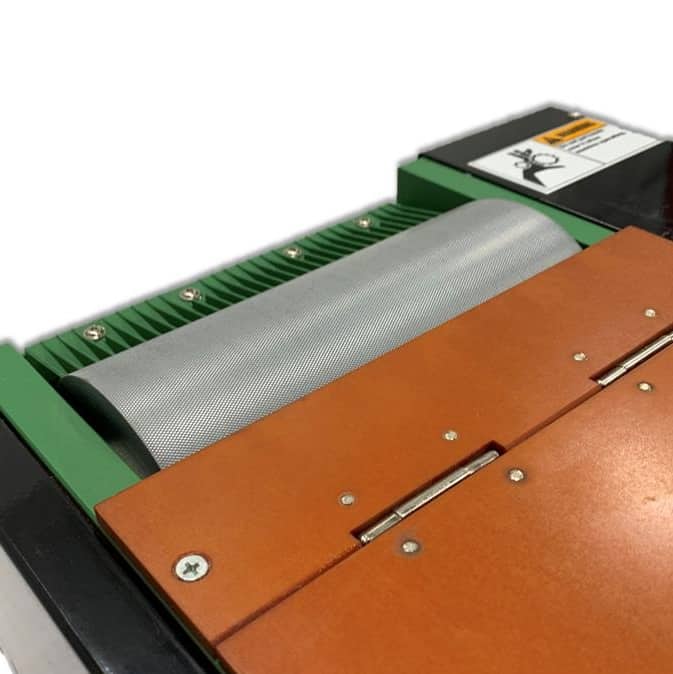

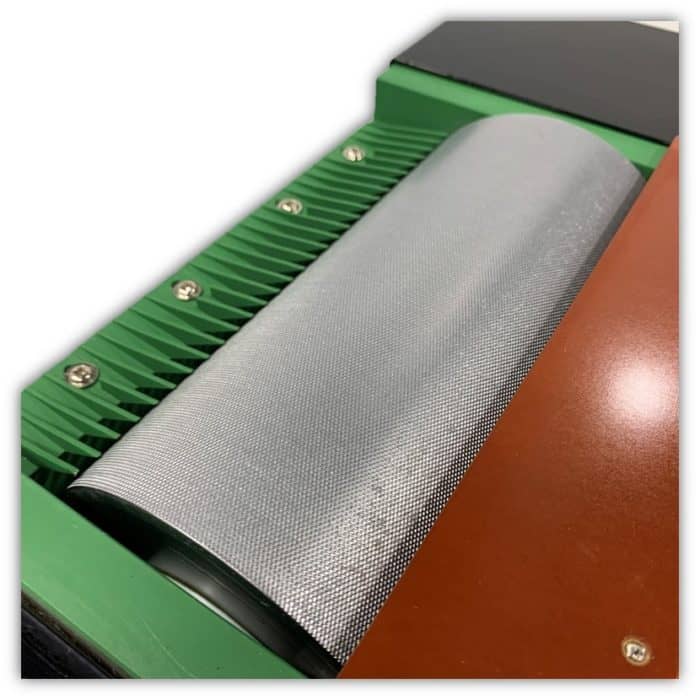

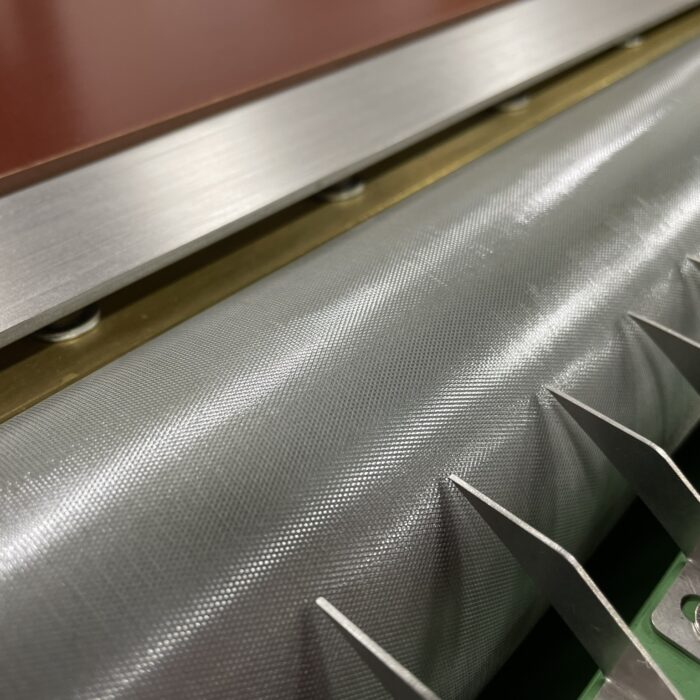

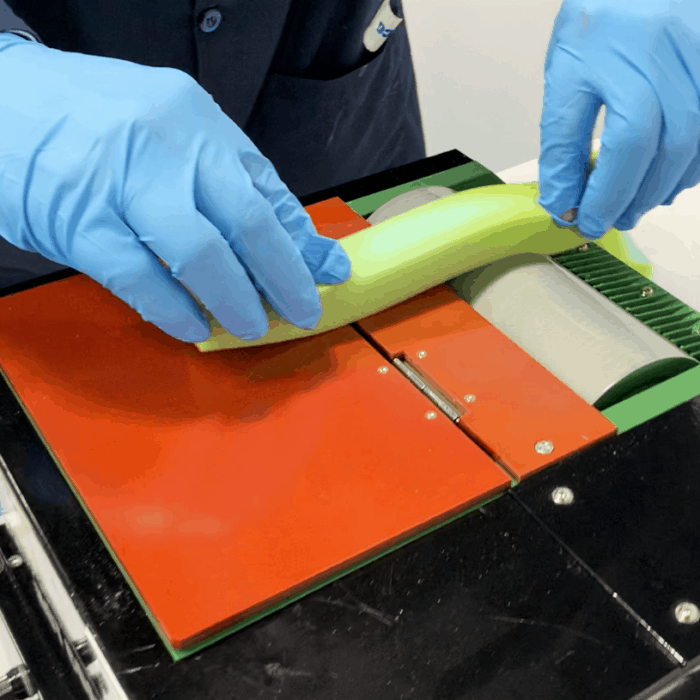

- Large Knurled Seperately Heated Coating Wheel for easy adhesive release to substrate with no stringing.

- Easily adjustable hot melt coat weight on wheel.

- Adjustable temperature controls for melter.

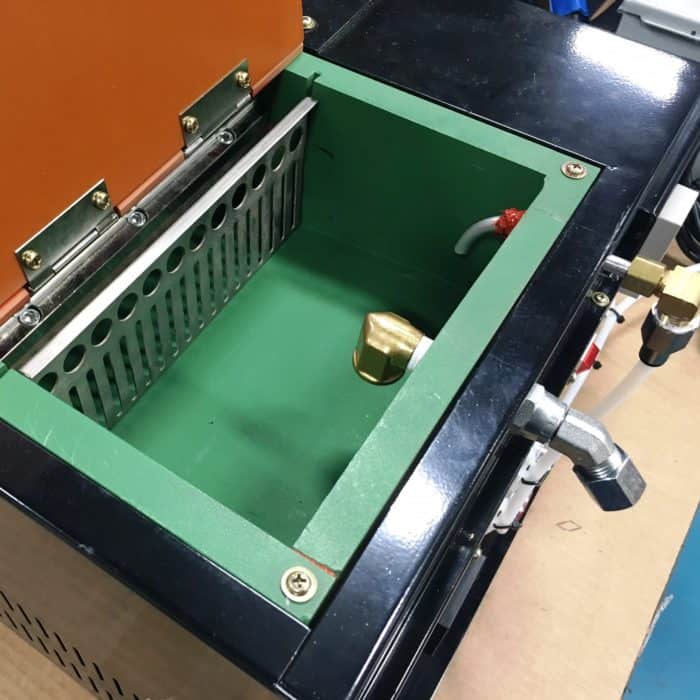

- Easy access to tank for removal of debris from substrates.

- Parts and service available with one phone call.

- 240V Single Phase, 2000 watts

- Hot Coat 7/Plus/Hot Coat 12/Plus Power Requirements: 240VAC=8.3 amp/1ph/50-60Hz.

- 7'8", 12 Gauge Power Cable Included to L620P Plug

- Max operating temperature of 428°F with a factory set (adjustable) low temperature motor enable/lockout out of 212°F

| Item | Machine Specifications |

| Power Supply Demand | 220 VAC / 50-60 Hz |

| Power | 2 KW |

| Net Weight | 95 lb. |

| Size (L x W x H: inches) | 18.625 x 12.25 x 17.75" |

| Tank Capacity (lbs) | 4.2 lb |

| Max Apply Width (inches) | 7.086" |

| Max Substrate Viscosity | .75" |

| Max Viscosity | 20,000 CPS |

| Max Melt Rate | 5.5 lb / hr |