Compatible With:

Most standard hot melt adhesives.Product Manuals / Related PDFs:

Manual available - Please callShot Pot™ Timer 1

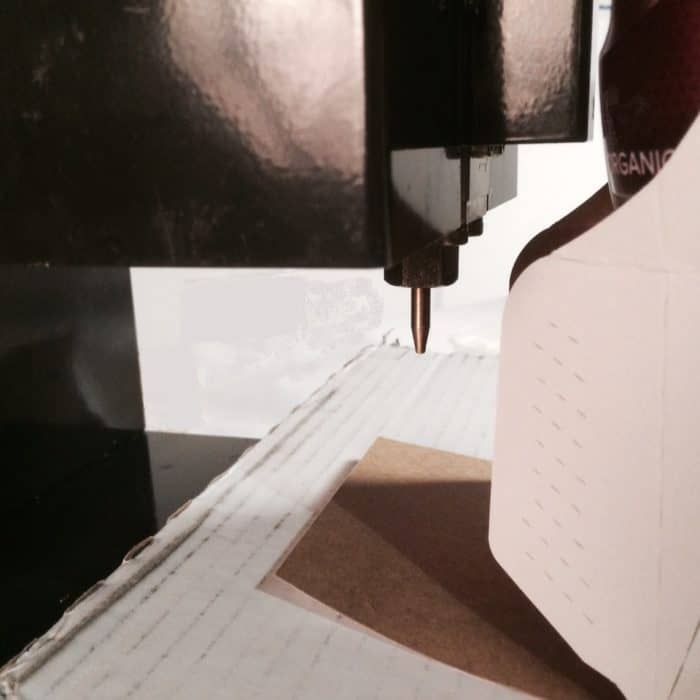

Foot switch activated benchtop hot melt metering system to apply precise, repeatable hot melt patterns to components moved under the nozzle.

$Product Videos (Click to View)

Carton Gluing with Dots1 2 Cycling Dots of Wax3 Wax on Wine Bottle4 Erecting, Filling, and Sealing Carton5 Fugitive Hot Melt to Label6 Dots on Small Cartons7 Four Dots on card wrap around flashing8 Glue drop9QUOTE THIS MACHINERY

Shot Pot™ Timer 1

Call 1-410-761-2727Or Fill Out The Form Below

Product Details:

- Complete "Turn-key" bench top hot melt extrusion system.

- Foot switch with cable to unit to actuate adhesive flow.

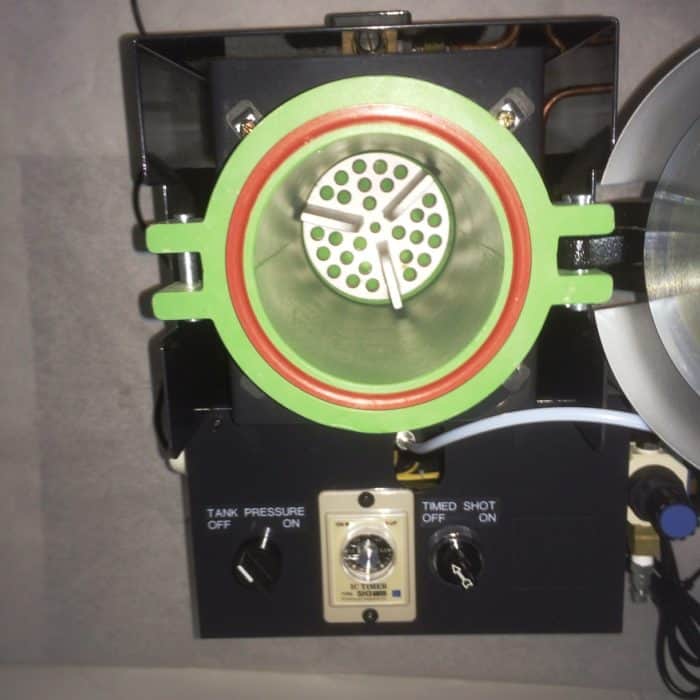

- 3.5 lb. hot melt tank capacity. Teflon lined.

- 3 to 5 lb. per hour melt rate depending on adhesive.

- Removable melt grid in bottom of tank.

- Thermostatic temperature controller

- Pneumatically adjustable adhesive flow control.

- High Speed valve/module for excellent adhesive shut off.

- Adjustable timer from .1 to 9 seconds for pre-measured adhesive patterns.

- Three nozzles and one extra tank seal included with purchase.

- Typical adhesive viscosities range between 500 and 5000 cps.

- Typical hot melt used with system are EVA's, APAO's, Polyamides, pressure sensitive and fugitive hot melts.

- Power Requirements : 120VAC 10amp/1ph/50-60Hz Not available in 240V Only Shot Pot Timer 2 available in 240V ( limited quantities available)

- Shot Pot/Shot Pot Timer 2 Power Requirements: 120VAC=10 amp/1ph/50-60Hz 240VAC=5 amp/1ph/50-60Hz

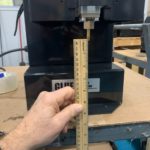

- Dimensions are 18" high x 15" wide x 13.5" deep.

- Weight is 32.5 lbs.

- Shot Pot Adapter Threads are 1/4BSPP.

- Compressed air required: 30-90 psi.

- Clearance nozzle to benchtop surface 7”Clearance nozzle to back of machine 7”Base can be reversed/ machine will be cantilevered

- Six month warranty against defective workmanship

- Method of shipping is UPS.