Exploring the Adhesion of Hot Glue to Wax Paper

Hot glue does adhere to wax paper to some extent, but the bond may not be very strong or reliable. The high temperature of… Read More!

Hot glue does adhere to wax paper to some extent, but the bond may not be very strong or reliable. The high temperature of… Read More!

In the realm of crafting, construction, and everyday repairs, glue sticks are a ubiquitous tool. Glue sticks, commonly made of synthetic polymers such as… Read More!

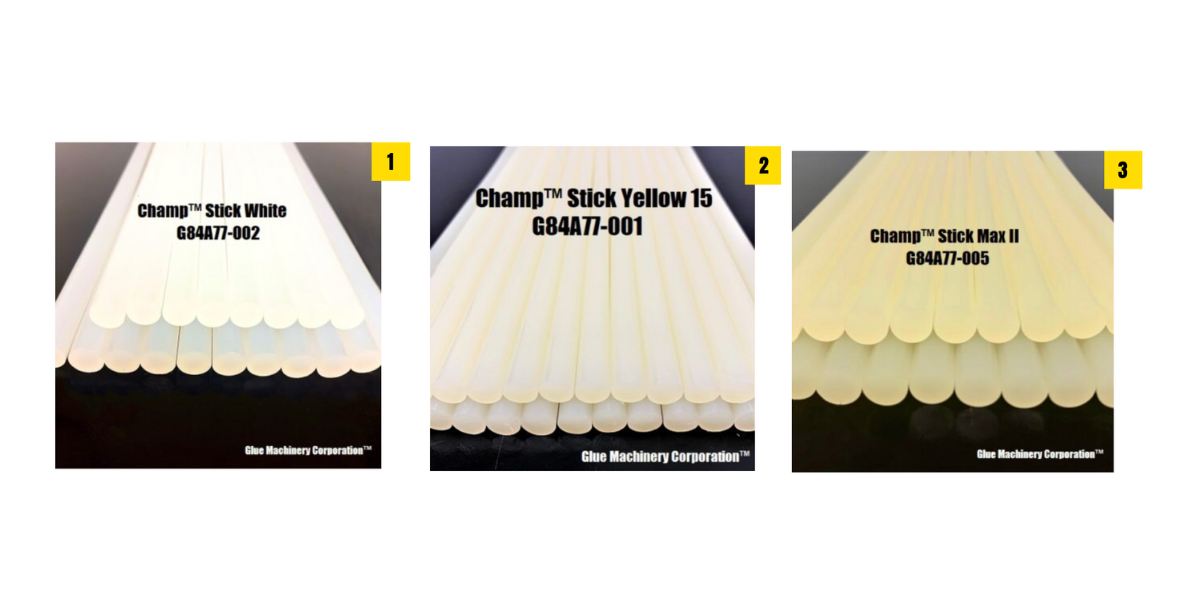

When it comes to adhesive solutions, glue sticks are among the most versatile and commonly used options. However, not all glue sticks are created… Read More!

Industrial glue sticks are versatile adhesive products commonly used across various industries and applications. One of the most common uses is in manufacturing and… Read More!

Hot melt pressure-sensitive adhesive (HMPSA) is a type of adhesive that is solid at room temperature but becomes soft and tacky when heated. It… Read More!

In the packaging industry, one component that plays a pivotal role in ensuring the integrity and reliability of packaging is the adhesive. Specifically, adhesives… Read More!

PUR adhesive stands for Polyurethane Reactive adhesive, a type of polymer that is used widely in various industrial and consumer applications due to its… Read More!

Industrial glue guns are an essential tool for manufacturers, production lines, and other commercial operations. With the right glue gun, you can optimize bonding… Read More!

Glues and adhesives are used in many crafts, repairs, and construction projects. However, not all glues are safe for items that will come in… Read More!

Woodworking projects require strong, fast bonds to assemble parts securely. Hot melt glue can provide quick adhesion for time-sensitive assemblies or temporary joints. With… Read More!