Compatible With:

Range of low viscosity hot melt adhesives.Product Manuals / Related PDFs:

Manual available - Please callShot Pot™ Hot Melt Glue System

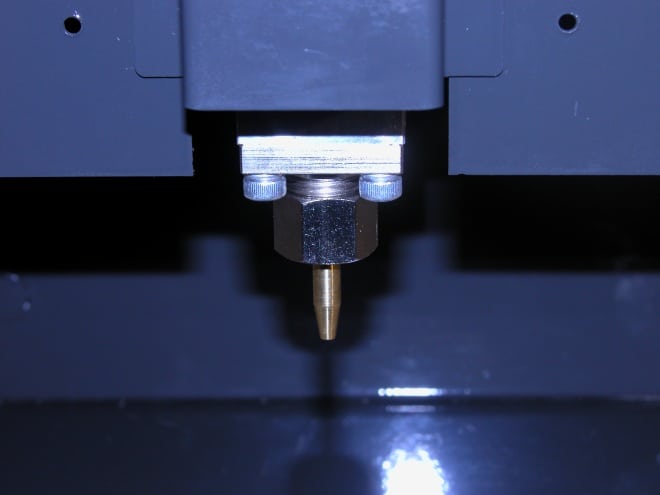

"Hands Free" hot melt benchtop applicator. Depress foot switch for the fast application of hot melt in bead form while substrate is easily moved under nozzle tip.

$QUOTE THIS MACHINERY

Shot Pot™ Hot Melt Glue System

Call 1-410-761-2727Or Fill Out The Form Below

Product Details:

- Complete "Hands Free" bench top hot melt system.

- Foot switch with cable to unit actuate adhesive flow.

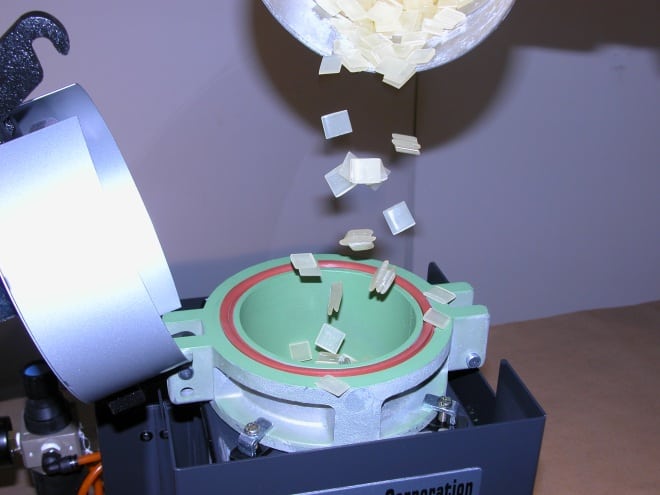

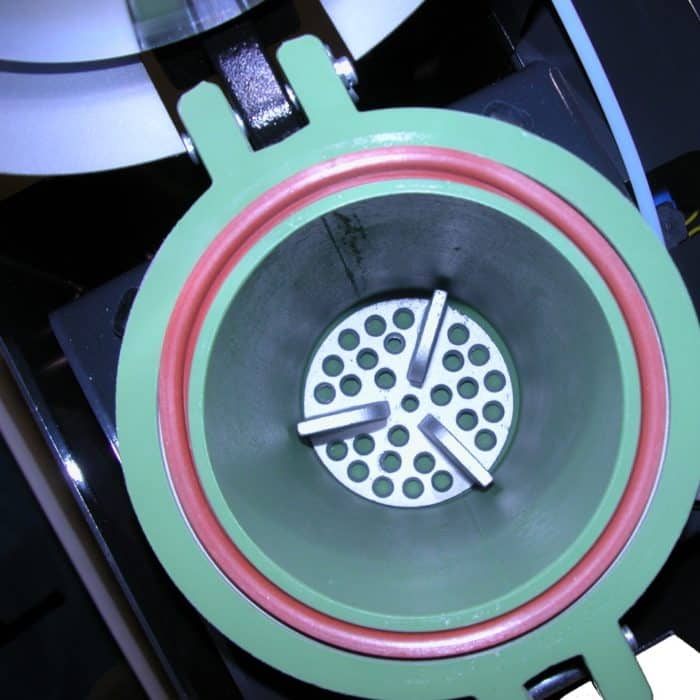

- 3.5 lb. hot melt tank capacity, Teflon lined.

- 3 to 5 lb. per hour melt rate depending on adhesive.

- Removable melt grid in bottom of tank.

- Thermostatically adjustable temperature controller. (In centigrade, 50-300ºC)

- Pneumatically adjustable adhesive flow control.

- Check Valve subassembly for good adhesive shut off.

- Three nozzles and one extra tank seal included with purchase.

- Typical Adhesive viscosities range between 500 and 5000 cps.

- Typical hot melts used with system are EVA's, APAO's,

- Polyamides, pressure sensitive and fugitive hot melts.

- Power requirements are 120VAC or 240VAC, 1200 W

- Dimensions are 17" high x 15" wide x 16" deep.

- Weight is 29 lbs.

- Shot Pot Adapter Threads are 1/4BSPP.

- Compressed air required: 30-90 psi.

- Six month warranty against defective workmanship.

- Method of Shipment is UPS.

- Shot Pot/Shot Pot Timer 2: 120VAC=10 amp/1ph/50-60Hz 240VAC=5 amp/1ph/50-60Hz