Updated November 19th, 2023

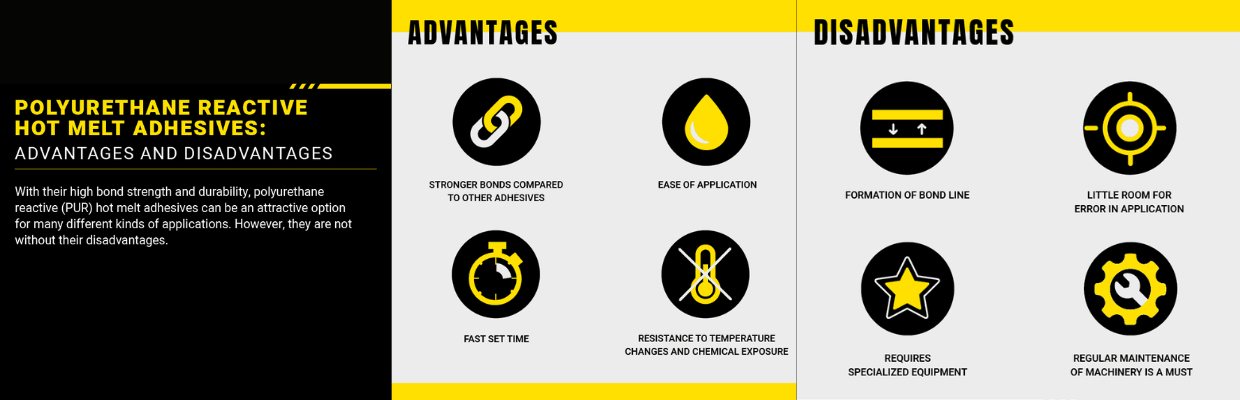

When deciding what kind of adhesive to use for your manufacturing, packaging and labeling needs, you may consider a moisture-curing polyurethane hot melt adhesive (PUR). With their high bond strength, polyurethane hot melts can be an attractive option for many different kinds of adhesive applications. However, polyurethane hot melts are not without their disadvantages as well. Let’s take a closer look at the pros and cons of using polyurethane hot melts for your particular adhesive needs.

Advantages of PUR Hot Melt Adhesives

Stronger than water-based & other hot-melts adhesives:

PUR hot melt draws moisture from the substrates and the atmosphere and cures to form a bond that is stronger than most other adhesives, including water-based adhesives as well as other hot melt adhesive formulations.

Short learning curve:

Because polyurethane hot melt adhesives are applied like other hot melt adhesives, using glue guns or similar equipment, operators can quickly get up to speed on applying best practices without having to learn all new processes and equipment.

Forms a bond quickly:

Polyurethane hot melt works quickly to form an extremely strong bond, with a fast set time. This allows you to quickly and confidently move through the manufacturing or packaging process with less concern about weak bonds or shifting substrates.

Other advantages:

Include strength, flexibility, temperature and chemical resistance. PUR can be used in a wide range of industries and has many applications.

Disadvantages of Polyurethane Hot Melt Adhesives

Bond line issues:

Unlike water-based adhesives that soak into the substrate, polyurethane hot melt adhesives stay on the surface of the materials. Because of this, a bond line can be created, which may be aesthetically unappealing or may even affect the product or packaging itself. This bond line needs to be accounted for in the production process.

Fast set time requires fast work:

Because PUR hot melt adhesive bonds quickly, it’s imperative to get the application right the first time. Less “forgiving” than other types of adhesives, polyurethane hot melt gives you a short window of time to apply the adhesive and make adjustments. Once that window is closed, the substrates aren’t going anywhere, so if you don’t get the exact result you want the first time you may need to start over.

Other disadvantages:

PUR equipment is considered very specialized and comes with an additional cost, and the maintenance on the production line must be adhered to – they are not very forgiving.

Frequently Asked Questions About PUR Hot Melt Adhesvies

How long does PUR glue last?

PUR glue typically has a shelf life of about one year after the bottle is opened. It’s important to note that this is an average estimate and can vary based on storage conditions and specific product formulations.

Is PUR glue waterproof?

PUR glue is known for its waterproof properties. It is designed to withstand exposure to water and other liquids without losing its strength, making it an ideal choice for applications requiring moisture resistance.

What is the solvent for PUR glue?

The best way to clean PUR glue is to use a specific solvent designed to dissolve the adhesive. Common solvents used for this purpose include methyl ethyl ketone (MEK) and acetone

What is PUR glue made of?

PUR glue is made by reacting two separate components: an isocyanate and a polyol. The isocyanate is usually made from either methylene diphenyl diisocyanate (MDI) or toluene diisocyanate (TDI), and the polyol can vary in chemical makeup, often being a blend of polyester or polyether.

What does polyurethane not stick to?

Polyurethane glue is effective on almost all types of materials, whether porous or non-porous. However, it may not perform well on polyethylene, polypropylene, or substances like silicone or Teflon

Is Polyurethane Hot Melt Right for Your Needs?

Clearly, there are a number of advantages and disadvantages when using PUR hot melts. Depending on your application, substrates and desired result, they may be a good choice for your business or you may be better served with a different type of adhesive. The best way to determine if a polyurethane hot melt adhesive is right for your business is to talk with an expert — like the glue experts here at Glue Machinery Corporation. Contact us today to learn more about your adhesive options and find out how our Glue Diligence program can help identify the best adhesive for your specific needs.