HMPSAs (Hot Melt Pressure Sensitive Adhesives) are typically composed of the following ingredients:

1. Styrenic Block Copolymers (SBCs)

SBCs offer cohesion, strength, and heat resistance for HMPSAs. Styrene phase forms a physically cross-linked network in the adhesive at room temperature. SBC melts and becomes flowable at the temperatures beyond the glass transition temperature of styrene domain, about 200 to 230°. Four typical SBCs are available in the hot melt adhesive market: Styrene-Isoprene-Styrene (SIS), Styrene-Butadiene-Styrene (SBS), Styrene-(Ethylene-Butylene)-Styrene (SEBS, the hydrogenated SBS), and Styrene-(Ethylene-Propylene)-Styrene (SEPS, the hydrogenated SIS). Each SBC has its own specific molecular structure and is able to formulate into specific formulations for diverse applications. Bound styrene (% styrene) and degree of coupling (% tri-block) included in the SBC; and melt flow rate (MFR) or Melt Index (MI) are three key molecular structures affecting adhesion performances and processability of HMPSAs.

2. Tackifiers

Tackifiers are low molecular weight oligomers based on petroleum or natural feedstock with softening points ranging from below room temperature to 320°. Tackifiers can provide specific adhesion and lower melt viscosity for adhesives.

Two families of tackifiers are commonly used for HMPSAs:

a) Petroleum hydrocarbon resins: C5 (aliphatic), C9 (aromatic), C10 (Di-Cyclo-PentaDiene, DCPD), C5/C9 (co-tackifiers), and C10/C9 (co-tackifiers).

b) Natural resins: Rosin, Terpene, and their derivatives.

The selection of tackifiers is primarily dependent upon the SBCs used and application markets. HMPSAs are clear or transparent when tackifiers and SBCs are compatible. For less or incompatible SBC-tackifier blends, they are cloudy or opaque.

3. Plasticizers

Plasticizers can efficiently reduce hardness, lower viscosity and improve low temperature resistance of HMPSAs. They can also lower adhesive cost. Two types of plasticizers are used in HMPSA formulations: mineral oils and butene oil. Mineral oil is a mixture containing various percentages of paraffinic, naththenic, and aromatic component. Different mineral oils may greatly affect adhesion performances, particularly for low temperature and high temperature resistance.

4. Antioxidants

Antioxidants are used to prevent or minimize degradation resulted from heat aging, mechanical shearing, and long term storage.

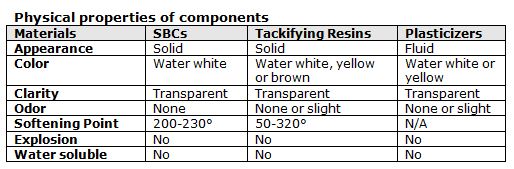

All the components used in the HMPSA formulations are 100% solid without volatile organic compounds. (Note: mineral oil is also considered as a 100% solid because it does not evaporate or heat loss during production and application.) They are safe, free of fire and explosion concerns, during production, storage, and application. Below are some physical properties of those used components.